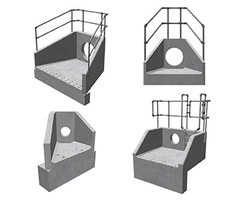

H7C A Headwall

H7C A Headwalls are precast concrete headwalls to suit plastic or clay pipes up to 600mm and concrete pipes up to 450mm. H7C A Headwalls have a backwall height of 1100mm. Stainless steel sockets can be cast into the headwall for the attachment of gratings and other factory fitted accessories.

H7C A Headwalls have a cast on concrete toe extension that extends 600mm below the base of the spillway headwall

We cast the opening in the back wall of our precast concrete headwalls to suit the pipe diameter and material of the pipe being used. We can cast multiple pipe openings, elliptical, square or rectangular culvert openings into any of our headwalls. We can also cast pipe openings into the wing walls of our headwalls.

The H7C A Headwall weighs 1450kg

We can offer coloured headwalls in 4 colours but the final shade is affected by many influences.

Natural

Cotswold

Agate

Raven Grey

Everglade

Brochures, Datasheets and Installation Instructions for H7C A Headwall

Free headwall design service

If you cannot find what you are looking for our Free Headwall Design Service can help.