Inline Penstocks

Althon have a standard range of inline penstocks for pipework up to 600mm. on request we are able to design and manufacture inline penstocks for project specific requirements.

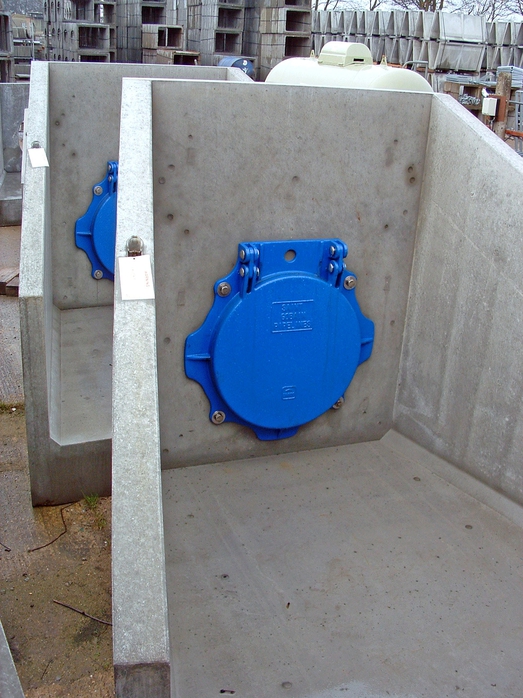

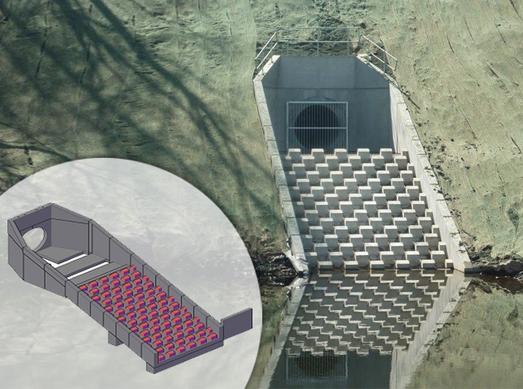

The penstock in this photograph was to connect to 1200mm pipework at a waste water treatment works. This particular penstock had an extended pipe connection on one side.

Our inline penstocks are typically manufactured in HDPE with grade 316L stainless steel reinforcements and fixings for a 50 year design life.

This was one of several large inline penstocks installed on this project and are believed to be some of the largest ever supplied in the UK

Penstocks are typically used to control the flow of water, shut off the flow of water for maintenance or in emergency situations or maintain and manage water levels.